Duotank is based on a unique concept where the beer is stored in airtight bags in pressurised tanks, known as the Bag-In-Tank principle. This system was originally developed for the distribution of pilsner beer produced by the major Dutch brands, and which is stored in chilled cellars under pubs and bars. Over the course of the years, however, Duotank has been developing the concept, and it can now be used in a wide variety of applications.

The specific advantages of the Duotank concept have led to it being increasingly adopted by microbreweries and brewpubs. This popularity is partly due to the fact that the beer retains its flavour longer after being connected to the beer taps, (many major breweries guarantee up to 12 weeks!), making it ideal for the specialty beers that often have somewhat lower turnover. This is because no extra CO2 needs to be added to the beer, and the beer is kept at a constant temperature and pressure; these factors significantly help preserve the quality of the beer and increase customers’ enjoyment of the flavour.

How the Bag-In-Tank system works

The basic system consists of a tank and a compressor with a pressure regulator. The tank is fitted with a spout in which the inliner (bag) and tap are mounted.

To control the pressure in the tank, the compressor is connected to a safety valve via the pressure regulator.

-

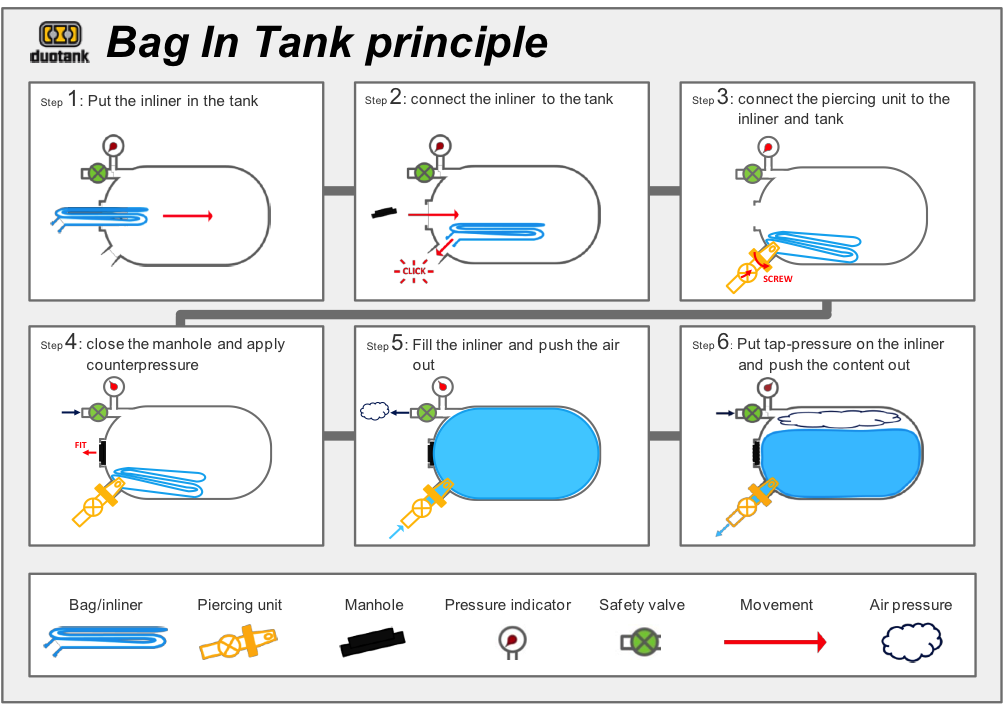

The manhole / inspection window is opened, and an empty bag (inliner) is placed in the tank.

-

The spout of this bag is connected to the tank spout.

-

Then the piercing unit is connected to the tank spout and tightened, which does two things. Firstly, an air-tight connection is created between the outside of the bag and the inside of the tank, and secondly, an air-tight and fluid-tight connection is created between the inside of the bag and the unit.

-

The manhole / inspection window is replaced, and the compressor creates a slight counter-pressure (+/- 1 to 1.5 bar) in the tank.

-

The beer line (fill hose) is connected to the piercing unit. Because the counter-pressure is kept lower than the filling pressure, the beer flows into the bag / tank. The counter-pressure prevents the beer from foaming.

-

To subsequently make the beer flow out of the tank, the air pressure on the bag in the tank is increased by the compressor. This pressure means that the beer is driven out of the bag to the serving tap at a constant rate.

Benefits of the Bag-in-Tank System

- No need to add CO2 to the beer:

- CO2 concentration in the beer can be optimised for flavour

- Over-saturation of CO2 in the beer no longer possible

- Save on CO2 cylinders.

- No more splattering from the beer tap when the tank is empty (caused by accumulation of CO2 in the beer line).

- Easy to switch to the next tank, and immediately continue serving beer.

- Reduces costs because polished tanks are not required (see below).

- Cleaning tanks is really simple (just rinse with water), and can be carried out on-site.

Sharply priced / easy cleaning:

The interiors of the tanks do not need to be hygienically polished, so they are much less expensive. And because the beer only comes into contact with the recyclable bags, it is much simpler and cheaper to clean the tank. The attached video shows the operations needed to exchange a bag in a chilled cellar beer tank. As Leonardo da Vinci said: simplicity is the ultimate sophistication.